I have been their biggest fan and biggest adversary, but here is what I found out about the Rage Broadheads.

In my 20 years of bowhunting, I have killed plenty of deer with all sorts of broadheads.

Long before the Rage Broadheads were a thing, I was shooting the Muzzy 85 grain and connected successfully on a handful of deer. I learned the importance of tuning your bow to your broadhead, not taking risky shots, and knowing my limitations.

Then this new broadhead appeared on the shelves, and was all bow hunters were talking about. I had to check out the Rage Broadhead and its patented expandable design. They flew like a field tip and left a massive wound channel; it was my new love.

Why I used to hate the Rage Broadheads

That was until I shot my number one hitlist buck back in 2012. The shot was at 55 yards, which I was completely comfortable with, but it went about four inches forward and hit nothing but shoulder.

There wasn't much penetration, there wasn't much blood, and I began to blame my broadhead for the failed success.

It wasn't until last fall when my good buddy shot a nice public land buck that left a massive blood trail. I thought to myself, maybe I will give them another try.

So in the spring, when turkey season came about, I was preparing a hunting trip that Scent Crusher and Cherokee Sports were putting on at the Hooray Ranch in Kansas. I decided I wanted to give the Rage Turkey Xtreme broadhead a shot.

What came next was the most embarrassing, ego-killing, yet knowledgeable experience I would go through since I began writing.

I was shooting my new Xpedition Xplorer SS, which was extremely accurate with the field tips. When I put the Rage Turkey Xtreme broadheads on, they not only missed the target, they flew way out of whack.

Instead of looking at the owner's manual orreading anything online, I immediately wrote an email. My job as a writer when I'm field testing products is to give the readers the truth. I want to cut through the marketing and give them the facts about products that they will be spending their hard earned money on.

So, I did what I thought was right, and I wrote Feradyne an email saying their broadheads do not work and they are a waste of my time. This would end up being the most embarrassing email I have ever written.

Why we're my broadheads flying so horribly?

My email was met back with an extremely concerned response, sent by someone who was willing to help me figure out what was wrong, rather than push me off to the side. I was met with a handful of solutions that could be causing the problem, but then followed up with a phone call from the engineering department to walk me through every possible thing that could be causing this problem.

The problem wasn't the broadhead, it was me. I was actually using the broadhead incorrectly. It's hard to believe this because I really thought I knew how the broadhead operated, I mean how hard could it be?

Here's what I was doing wrong:

Rage Broadhead Collar

See the arrow on the bottom side of this collar? I didn't. This arrow is important in that the blades from the broadhead should line up with this arrow. I missed this memo.

In fact, I thought the broadheads lined up with the slots in the collar, not the middle of the petals.

The arrow bisects the petals just as the blades from the broadhead should. This was the majority of my problem and I could have easily hung up the phone and went out and shot my bow again, but I wanted to know more.

The Rage Broadhead Collar

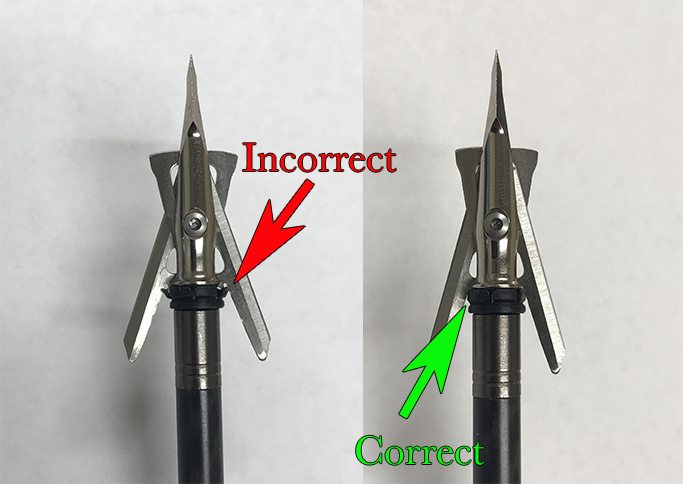

If ensuring the blades weren't in the right spot wasn't easy enough, there is more.

As Ryan, Engineering Director of Feradyne Outdoors, spoke to me on the phone, he described having a properly seated shock collar. This is much easier to explain with pictures so he sent me over two photos to share the difference between a correct and incorrectly seated shock collar.

Feradyne Outdoors

Although it is not common, but if seated incorrectly, it could be a factor in pre-deployment.

To eliminate that possibility, you will want to ensure your blades are properly seated. On the bottom of each blade are two flat ends to which are not sharpened.

Here is the safest place for you to hold and pinch the broadhead while screwing on the arrow. If you use one hand to turn the arrow and the other to pinch the broadhead, as the broadhead tightens, the collar should seat over the blades properly.

Failure to pinch the broadhead could cause it to seat incorrectly like the image on the left which shows sign of pressure from the blades on the shock collar petal.

To ensure the most dependable performance from your rage broadhead, you need to ensure the blades are lined up bisect the petal as well as seat correctly like the image on the right.

Pre-deployment testing of the Rage Broadheads

The testing phase of the Rage Broadhead was the biggest reason I decided to shoot them again this season. The broadheads are tested for a multitude of performance metrics.

They are first tested for against pre-deployment. For vertical bows, this is done by shooting a bow at 80 lbs with a 30" draw length and full length arrows through tuning paper.

As the arrow is shot through the paper, and if a broadhead pre-deploys during or after the launch, the test will display blade slits in the paper. The broadheads must pass a pre-deployment test before even considering moving forward with the other tests.

Testing the "Slap Cut"

Feradyne Outdoors uses a Hooter Shooter to eliminate human error when testing their broadheads.

To ensure the broadhead has proper blade deployment in both the upper and lower limits of bow, this test is completed using a bow at 80 lbs with a 30" draw and a 35 lb bow with a 25" draw length. The broadheads are then shot into ballistic gel covered in a tanned deer hide.

This test determines the "Slap Cut" ensuring the broadhead properly deploys in lower and higher draw lengths and weight.

This test does not result in a suggestion for hunters to use a specific broadhead with a 35 lb bow. It simply indicates the total assembly as designed.

Testing penetration

In testing the "Slap Cuts" of the broadhead using the deer hide and ballistics gel, another test is documented. The depth of penetration is documented along with the blade path upon impact.

This is completed with a 70 lb draw weight and a 30" draw length bow.

This test is standardized across all broadheads regardless of fixed, expandable or hybrid. The result is the value of inches of what the broadhead will perform.

Testing the durability of the Rage Broadheads

In addition to the above tests, the broadheads are also tested for durability. This is a series of shots through half-inch chipboard at 90 degree angle, or straight on. This test shows the blade strength through impact as well as the structural integrity of the ferrule.

In addition, the broadheads are then tested with the chipboard at a 45 degree angle. This test is completed for a couple reasons.

The first takes into account the lateral stress exerted on the assembly. This validates the structural integrity. Additionally, this test will result in any geometry on the structure that would aid in deflecting the broadhead rather than allowing for penetration.

Of course, you want your broadhead to fully penetrate and never deflect regardless of the angle, so this test is completed and deemed a vital process of the testing of the broadhead.

How accurate are the Rage Broadheads?

As I mentioned before, I stopped shooting Rage Broadheads after a non-lethal shot on my number one hitlist buck. I didn't want to admit that it could possibly had been my fault.

The truth is, and now confirmed, it was my fault. We all know that no matter the broadhead, an accurate heart shot will kill a deer.

We also know after a recent survey that accuracy is amongst the most important factor for bow hunters. Feradyne Outdoors understands this and puts all of their broadheads to the test before they ever leave the manufacturer.

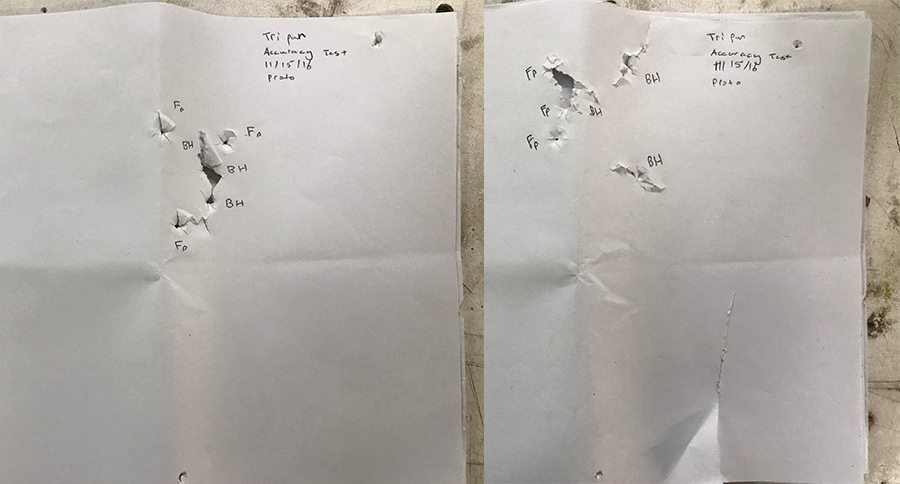

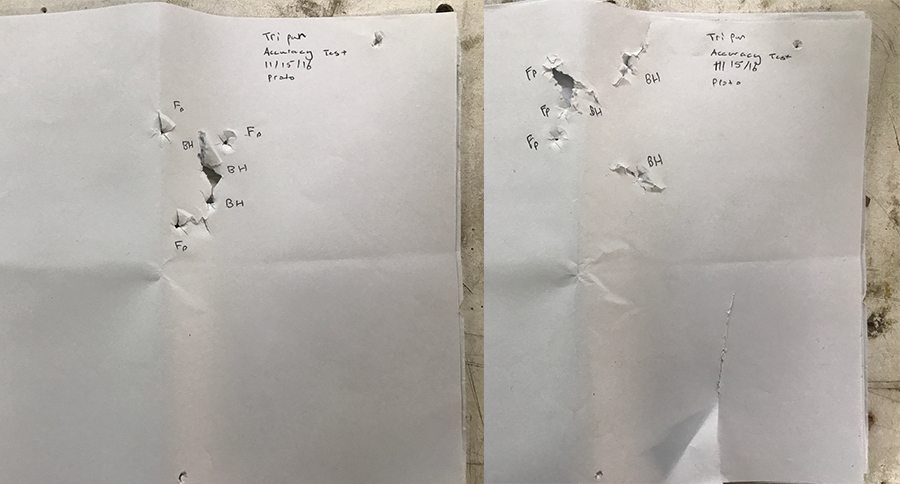

The test is completed at 50 yards. There are a series of iterations of arrows with field points into a blank page of paper. After the shot, the arrows are pulled and examined to ensure the arrows were not destroyed in the first round of testing.

If the slightest of flaws are found in any of the arrows, the test is voided and a new test begins.

Rage Accuracy Test

The arrows are shot in groups of five. After shooting with the field points, the test is repeated using the same piece of paper with the broadheads. This is done to identify the group of both the field points and the broadheads.

The test is completed six times to make sure to eliminate any anomalies in the performance.

The end result looks like the above image showing the broadheads in correlation with the field points. The expectation is that the group of broadheads are no more than two and a half inches from the group of field points.

To ensure consistency and eliminate possible human error, all of these tests are completed using a Hooter Shooter (as seen in the photo above). The tests are also completed using a multitude of bows. This is to ensure the performance is across the board for multiple brands, not just one in particular.

Bottom line, there are so many factors that can lead to your failure in the field. We, as hunters, often blame it initially on our equipment as that is the easiest scapegoat. Feradyne and Rage, have made it so I can no longer use that excuse but have assured me that the next time I take a shot on my number one hitlist buck, four inches off at 50 yards is at the very least, not my broadhead.

At the end of the day, knowing your equipment, practicing relentlessly and practicing ethical hunting measures can only increase your chance in the field.

Like what you see here? You can read more articles by Dustin Prievo here. Follow him and his hunting team, Top Pin Outdoors, on Twitter, Facebook and Instagram.

NEXT: DeerLab: The Trail Camera Software Made For Serious Hunters