Watch how this company makes their airguns from start to finish.

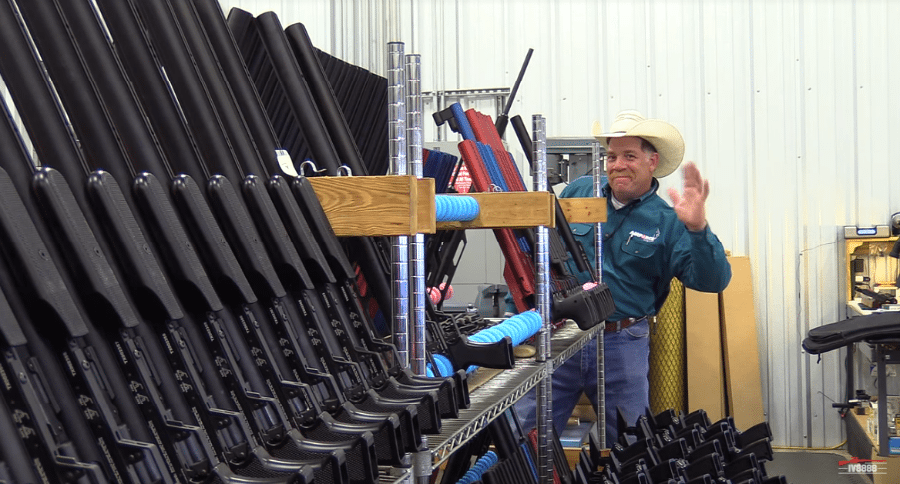

Eric from the YouTube channel Iraqveteran8888 takes us on a tour of the new Airforce Airguns factory located in Fort Worth, Texas. It's quite a facility.

Eric shows the multiple steps in the process of assembling an Airforce air rifle. It starts with the warehousing of the "raw material" pieces, and moves on to the machining, tumbling, blasting and anodizing of various components.

At the end, the guns are run through a quality control process and tested.

I thought one interesting tidbit was the fact the company gets its barrels from the German barrel manufacturer Lothar Walther.

Lothar Walther makes a variety of gun barrels, including several new barrels for AR-15 and AR-10 platforms.

Airforce Airguns makes, I believe, five basic models of airguns: the Edge target rifle, the Condor, Escape and Talon utility airguns, as well as the big-bore Texan. There are also various models of these basic formats.

Iraqveteran8888 has released at least a couple of other videos highlighting the Airforce big-bore Texan model. In one of their videos, they shot the Texan for distance and achieved a lethal range of over 600 yards with a .45-caliber slug.

These airguns are not toys. They're lethal hunting and target rifles. Modern pneumatic weapons are a long way from the old Red Ryder BB guns of yesteryear. You'll do a lot more than shooting your eye out with one of these.

Like what you see here? You can read more great articles by David Smith at his Facebook page, Stumpjack Outdoors.

NEXT: BENJAMIN PIONEER AIRBOW FIRES ARROWS AT 450 FPS

https://rumble.com/embed/u7gve.v3v4j9/